Jeep Cherokee (XJ): Adapter housing. Speedometer adapter. Park/neutral position switch

REMOVAL (1) Hoist and support vehicle on safety stands.

(2) Support transmission with a suitable lifting

device.

(3) Remove transmission skid plate. Refer to

Group 13, Frame and Bumpers, for proper procedure.

1 - REMOVER 6957

1 - SPECIAL TOOL C-4171 (4) Remove propeller shafts. Refer to Group 3, Differential

and Driveline, for proper procedure.

(5) Remove transfer case.

(6) Remove bolts holding adapter housing to transmission

case (Fig. 75).

(7) Separate adapter housing from transmission.

(8) Slide adapter housing rearward and off output

shaft (Fig. 75). INSTALLATION Clear gasket material from sealing surfaces on

adapter housing and rear of transmission. Replace

output shaft bearing, if necessary.

(1) Install new rear seal in adapter housing. Use

Tool Handle C-4171 and Seal Installer C-3860-A to

install seal.

(2) Place adapter housing gasket in position on

rear of transmission.

(3) Slide adapter housing forward and over output

shaft (Fig. 75).

1 - TRANSMISSION (4) Guide park shaft into park sprag and push

adapter housing forward until rod passes through

opening behind sprag. It may be necessary to use a

wire to hold sprag to the side for rod to pass through.

(5) Install bolts to hold adapter housing to rear of

transmission.

(6) Install transfer case.

(7) Install propeller shafts.

(8) Install rear transmission mount and skid plate.

(9) Lower vehicle and verify transmission fluid

level. Add fluid as necessary. Rear axle gear ratio and tire size determine speedometer

pinion requirements. REMOVAL (1) Raise vehicle.

(2) Disconnect wires from vehicle speed sensor.

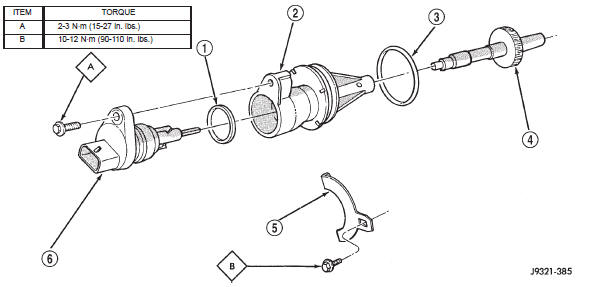

(3) Remove adapter clamp and screw (Fig. 76).

(4) Remove speed sensor and speedometer adapter

as assembly.

(5) Remove speed sensor retaining screw and

remove sensor from adapter.

(6) Remove speedometer pinion from adapter.

(7) Inspect sensor and adapter O-rings (Fig. 76).

Remove and discard O-rings if worn or damaged.

(8) Inspect terminal pins in speed sensor. Clean

pins with Mopart electrical spray cleaner if dirty or

oxidized. Replace sensor if faulty, or pins are loose,

severely corroded, or damaged. INSTALLATION (1) Thoroughly clean adapter flange and adapter

mounting surface in housing. Surfaces must be clean for proper adapter alignment

and speedometer operation.

(2) Install new O-rings on speed sensor and speedometer

adapter if necessary (Fig. 76).

(3) Lubricate sensor and adapter O-rings with

transmission fluid.

(4) Install vehicle speed sensor in speedometer

adapter. Tighten sensor attaching screw to 2-3 N·m

(15-27 in. lbs.) torque.

(5) Install speedometer pinion in adapter.

(6) Count number of teeth on speedometer pinion.

Do this before installing assembly in housing. Then

lubricate pinion teeth with transmission fluid.

(7) Note index numbers on adapter body (Fig. 77).

These numbers will correspond to number of teeth on

pinion.

(8) Install speedometer assembly in housing.

(9) Rotate adapter until required range numbers

are at 6 o'clock position. Be sure range index numbers

correspond to number of teeth on pinion gear.

(10) Install speedometer adapter clamp and retaining

screw. Tighten clamp screw to 10-12 N·m (90-110

in. lbs.) torque.

(11) Connect wires to vehicle speed sensor.

(12) Lower vehicle and top off transmission fluid

level, if necessary.

1 - SPEEDOMETER ADAPTER REMOVAL (1) Raise vehicle and position drain pan under

switch.

(2) Disconnect switch wires.

(3) Remove switch from case.

1 - SENSOR O-RING INSTALLATION (1) Move shift lever to Park and Neutral positions.

Verify that switch operating lever fingers are centered

in switch opening in case (Fig. 78).

1 - NEUTRAL CONTACT 2) Install new seal on switch and install switch in

case. Tighten switch to 34 N·m (25 ft. lbs.) torque.

(3) Test continuity of new switch with 12V test

lamp.

(4) Connect switch wires and lower vehicle.

(5) Top off transmission fluid level.Adapter housing

Fig. 73 Bushing Removal-Typical

2 - EXTENSION HOUSING BUSHING

Fig. 74 Extension Housing Seal Installation

2 - SPECIAL TOOL C-3995-A

Fig. 75 Adapter Housing

2 - GASKET

3 - ADAPTER HOUSINGSpeedometer adapter

Fig. 77 Index Numbers On Speedometer Pinion Adapter

2 - INDEX NUMBER LOCATIONPark/neutral position switch

Fig. 76 Speedometer Pinion Adapter Components

2 - SPEEDOMETER ADAPTER>

3 - ADAPTER O-RING>

4 - SPEEDOMETER PINION>

5 - ADAPTER CLAMP>

6 - VEHICLE SPEED SENSOR

Fig. 78 Park/Neutral Position Switch

2 - MANUAL LEVER AND SWITCH PLUNGER IN REVERSE

POSITION

3 - PARK CONTACT

4 - SWITCH

Torque converter. Yoke seal replacement. Extension housing bushing

Torque converter. Yoke seal replacement. Extension housing bushing

Gearshift cable. Brake transmission shift interlock. Valve body

Gearshift cable. Brake transmission shift interlock. Valve body

Other materials:

Off-road driving tips

When To Use 4WD LOW Range

When off-road driving, shift to 4WD LOW for additional

traction and control on slippery or difficult terrain,

ascending or descending steep hills, and to increase

low-speed pulling power (refer to "All Wheel Drive and

Four-Wheel Drive Operation" in this section for furt ...