Jeep Cherokee (XJ): Cleaning and inspection. Adjustments. Specifications

Wash differential components with cleaning solvent

and dry with dry compressed air. Do not steam

clean the differential components.

Wash bearings with solvent and towel dry, or dry

with compressed air. DO NOT spin bearings with

compressed air. Cup and bearing must be

replaced as matched sets only.

Be sure that the axle tubes and oil channels are

thoroughly cleaned in the housing.

Inspect for: Polish each axle shaft sealing surface with No. 600

crocus cloth. This can remove slight surface damage.

Do not reduce the diameter of the axle shaft seal contact

surface. When polishing, the crocus cloth should

be moved around the circumference of the shaft (not

in-line with the shaft). Clean all components in cleaning solvent. Dry components

with compressed air. Inspect clutch pack

plates for wear, scoring or damage. Replace both

clutch packs if any one component in either pack is

damaged. Inspect side gears and pinions. Replace

any gear that is worn, cracked, chipped or damaged.

Inspect differential case and pinion shaft. Replace if

worn or damaged. PRESOAK PLATES AND DISC Plates and discs with fiber coating (no grooves or

lines) must be presoaked in Friction Modifier before

assembly. Soak plates and discs for a minimum of 20

minutes. GENERAL INFORMATION Ring gears and pinions are supplied as matched

sets only. The identifying numbers for the ring gear

and pinion are etched into the face of each gear (Fig.

51). A plus (+) number, minus (-) number or zero (0)

is etched into the face of the pinion. This number is

the amount (in thousandths of an inch) the depth

varies from the standard depth setting of a pinion

etched with a (0). The standard depth provides the

best gear tooth contact pattern. Refer to Backlash

and Contact Pattern Analysis paragraph in this section

for additional information.

1 - PRODUCTION NUMBERS Compensation for pinion depth variance is

achieved with select shims. The shims are placed

behind the rear pinion bearing (Fig. 52).

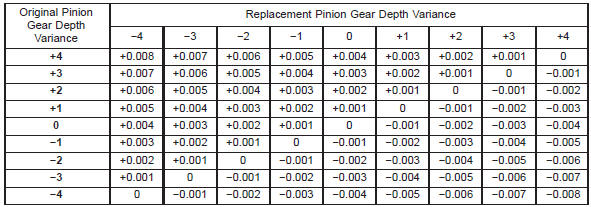

If a new gear set is being installed, note the depth

variance etched into both the original and replacement

pinion. Add or subtract the thickness of the

original depth shims to compensate for the difference

in the depth variances. Refer to the Depth Variance

chart.

Note where Old and New Pinion Marking columns

intersect. Intersecting figure represents plus or

minus the amount needed.

Note the etched number on the face of the pinion

gear head (-1, -2, 0, +1, +2, etc.). The numbers represent

thousands of an inch deviation from the standard.

If the number is negative, add that value to the

required thickness of the depth shims. If the number

is positive, subtract that value from the thickness of

the depth shim. If the number is 0 no change is necessary.

1 - AXLE HOUSING PINION DEPTH MEASUREMENT AND ADJUSTMENT Measurements are taken with pinion bearing cups

and pinion bearings installed in the axle housing.

Take measurements with Pinion Gauge Set and Dial

Indicator C-3339 (Fig. 53).

(1) Assemble Pinion Height Block 6739, Pinion

Block 8540, and rear pinion bearing onto Screw 6741

(Fig. 53).

(2) Insert assembled height gauge components,

rear bearing, and screw into axle housing through

pinion bearing cups (Fig. 54).

(3) Install front pinion bearing and Cone-Nut 6740

hand tight (Fig. 53).

(4) Place Arbor Disc 8541 on Arbor D-115-3 in position

in axle housing side bearing cradles (Fig. 55).

Install differential bearing caps on Arbor Discs and

tighten cap bolts to 41 N·m (30 ft. lbs.).

NOTE: Arbor Discs 8541 has different step diameters

to fit other axles. Choose proper step for axle

being serviced.

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(6) Place Scooter Block/Dial Indicator in position

in axle housing so dial probe and scooter block are

flush against the rearward surface of the pinion

height block (Fig. 53). Hold scooter block in place and

zero the dial indicator face to the pointer. Tighten

dial indicator face lock screw. PINION GEAR DEPTH VARIANCE

1 - DIAL INDICATOR (7) With scooter block still in position against the

pinion height block, slowly slide the dial indicator

probe over the edge of the pinion height block.

(8) Slide the dial indicator probe across the gap

between the pinion height block and the arbor bar

with the scooter block against the pinion height block

(Fig. 56). When the dial probe contacts the arbor bar,

the dial pointer will turn clockwise. Bring dial

pointer back to zero against the arbor bar, do not

turn dial face. Continue moving the dial probe to the

crest of the arbor bar and record the highest reading.

If the dial indicator can not achieve the zero reading,

the rear bearing cup or the pinion depth gauge set is

not installed correctly.

(9) Select a shim equal to the dial indicator reading

plus the drive pinion gear depth variance number

etched in the face of the pinion (Fig. 51). For example,

if the depth variance is -2, add +0.002 in. to the

dial indicator reading. The following must be considered when adjusting

bearing preload and gear backlash:

1 - ARBOR DISC

1 - ARBOR NOTE: The differential bearing cups will not always

immediately follow the threaded adjusters as they

are moved during adjustment. To ensure accurate

bearing cup responses to the adjustments: (1) Use Wrench C-4164 to adjust each threaded

adjuster inward until the differential bearing freeplay

is eliminated (Fig. 57). Allow some ring gear

backlash (approximately 0.01 inch/0.25 mm) between

the ring and pinion gear. Seat the bearing cups with

the procedure described above.

1 - AXLE TUBE (2) Install dial indicator and position the plunger

against the drive side of a ring gear tooth (Fig. 58).

Measure the backlash at 4 positions (90 degrees

apart) around the ring gear. Locate and mark the

area of minimum backlash.

(3) Rotate the ring gear to the position of the least

backlash. Mark the gear so that all future backlash

measurements will be taken with the same gear

teeth meshed.

(4) Loosen the right-side, tighten the left-side

threaded adjuster. Obtain backlash of 0.003 to 0.004

inch (0.076 to 0.102 mm) with each adjuster tightened

to 14 N·m (10 ft. lbs.). Seat the bearing cups

with the procedure described above.

(5) Tighten the differential bearing cap bolts 95

N·m (70 ft. lbs.).

(6) Tighten the right-side threaded adjuster to 102

N·m (75 ft. lbs.). Seat the bearing cups with the procedure described above.

Continue to tighten the

right-side adjuster and seat bearing cups until the

torque remains constant at 102 N·m (75 ft. lbs.)

(7) Measure the ring gear backlash. The range of

backlash is 0.006 to 0.008 inch (0.15 to 0.203 mm).

(8) Continue increasing the torque at the rightside

threaded adjuster until the specified backlash is

obtained.

1 - DIAL INDICATOR (7) Measure the ring gear backlash. The range of

backlash is 0.006 to 0.008 inch (0.15 to 0.203 mm).

(8) Continue increasing the torque at the rightside

threaded adjuster until the specified backlash is

obtained.

NOTE: The left-side threaded adjuster torque

should have approximately 102 N·m (75 ft. lbs.). If

the torque is considerably less, the complete

adjustment procedure must be repeated.

(9) Tighten the left-side threaded adjuster until

102 N·m (75 ft. lbs.) torque is indicated. Seat the

bearing rollers with the procedure described above.

Do this until the torque remains constant.

(10) Install the threaded adjuster locks and

tighten the lock screws to 10 N·m (90 in. lbs.).

After the proper backlash is achieved, perform the

Gear Contact Analysis procedure. The ring gear and pinion teeth contact patterns

will show if the pinion depth is correct in the axle

housing. It will also show if the ring gear backlash

has been adjusted correctly. The backlash can be

adjusted within specifications to achieve desired

tooth contact patterns.

(1) Apply a thin coat of hydrated ferric oxide, or

equivalent, to the drive and coast side of the ring

gear teeth.

(2) Wrap, twist, and hold a shop towel around the

pinion yoke to increase the turning resistance of the

pinion. This will provide a more distinct contact pattern.

(3) Using a boxed end wrench on a ring gear bolt,

Rotate the differential case one complete revolution

in both directions while a load is being applied from

shop towel.

The areas on the ring gear teeth with the greatest

degree of contact against the pinion teeth will squeegee

the compound to the areas with the least amount

of contact. Note and compare patterns on the ring

gear teeth to Gear Tooth Contact Patterns chart (Fig.

59) and adjust pinion depth and gear backlash as

necessary. When measuring side gear clearance, check each

gear independently. If it necessary to replace a side

gear, replace both gears as a matched set.

(1) Install the axle shafts and C-locks and pinion

mate shaft.

(2) Measure each side gear clearance. Insert a

matched pair of feeler gauge blades between the gear

and differential housing on opposite sides of the hub

(Fig. 60).

(3) If side gear clearances is no more than 0.005

inch. Determine if the axle shaft is contacting the

pinion mate shaft. Do not remove the feeler

gauges, inspect the axle shaft with the feeler

gauge inserted behind the side gear. If the end of

the axle shaft is not contacting the pinion mate

shaft, the side gear clearance is acceptable.

(4) If clearance is more than 0.005 inch (axle shaft

not contacting mate shaft), record the side gear clearance.

Remove the thrust washer and measure its

thickness with a micrometer. Add the washer thickness

to the recorded side gear clearance. The sum of

gear clearance and washer thickness will determine

required thickness of replacement thrust washer

(Fig. 61).

In some cases, the end of the axle shaft will move

and contact the mate shaft when the feeler gauge is

inserted. The C-lock is preventing the side gear from

sliding on the axle shaft.

(5) If there is no side gear clearance, remove the

C-lock from the axle shaft. Use a micrometer to measure

the thrust washer thickness. Record the thickness

and re-install the thrust washer. Assemble the

differential case without the C-lock installed and remeasure

the side gear clearance.

(6) Compare both clearance measurements. If the

difference is less than 0.012 inch (0.305 mm), add

clearance recorded when the C-lock was installed to

thrust washer thickness measured. The sum will

determine the required thickness of the replacement

thrust washer.

1 - FEELER GAUGE BLADES

(7) If clearance is 0.012 inch (0.305 mm) or

greater, both side gears must be replaced (matched

set) and the clearance measurements repeated.

(8) If clearance (above) continues to be 0.012 inch

(0.305 mm) or greater, the case must be replaced. Axle Type . . . . . . . . . . . . . . . Semi-floating, hypoid Differential Case Clearance . . . . . . . . . . . . . 0.12 mm (0.005 in.) Ring Gear Diameter . . . . . . . . . . . . . . . . . . 20.95 cm (8.25 in.) Pinion Bearing Preload-Used Bearings . . . . 1-2 N·m (10-20 in.lbs.) DESCRIPTION TORQUE Diff. Cover Bolt . . . . . . . . . . . . . 41 N·m (30 ft. lbs.)Cleaning and inspection

8 1/4 Axle

Trac-lok

Adjustments

1/4 Axle pinion gear depth

Fig. 51 Pinion Gear ID Numbers

2 - DRIVE PINION GEAR DEPTH VARIANCE

3 - GEAR MATCHING NUMBER (SAME AS RING GEAR

NUMBER)

Fig. 52 Shim Locations

2 - COLLAPSIBLE SPACER

3 - PINION BEARING

4 - PINION DEPTH SHIM

5 - PINION GEAR

6 - BEARING CUP

Fig. 53 Pinion Gear Depth Gauge Tools-Typical

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 54 Pinion Height Block-TypicalDifferential bearing preload and

gear backlash

Fig. 55 Gauge Tools In Housing-Typical

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 56 Pinion Gear Depth Measurement-Typical

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 57 Threaded Adjuster Tool

2 - BACKING PLATE

3 - TOOL C-4164

Fig. 58 Ring Gear Backlash Measurement

2 - RING GEAR

3 - EXCITER RINGGear contact pattern analysis

Side gear clearance

Fig. 59 Gear Tooth Contact Patterns

Fig. 60 Side Gear Clearance Measurement

2 - SIDE GEAR

Fig. 61 Side Gear CalculationsSpecifications

8 1/4 Inch axle

Lubricant . . . . . . . . . . . . . . . . . . . . . . SAE 80W-90

Lube Capacity . . . . . . . . . . . . . . . . 2.08 L (4.4 pts.)

Trac-Lok Additive . . . . . . . . . . . . . . . 118 ml (4 oz.)

Axle Ratio . . . . . . . . . . . . . . . . . . . . 3.07, 3.55,.4.10

Case Flange Runout . . . . . . . . 0.076 mm (0.003 in.)

Backlash . . . . . . . . . 0.12-0.20 mm (0.005-0.008 in.)

Runout . . . . . . . . . . . . . . . . . . 0.127 mm (0.005 in.)

Preload-New Bearings . . . . . 1-5 N·m (10-30 in.lbs.)8 1/4 Inch axle

Bearing Cap Bolt . . . . . . . . . . 136 N·m (100 ft. lbs.)

Pinion Nut-Minimum . . . . . . 285 N·m (210 ft. lbs.)

Ring Gear Bolt . . . . . . . . . . . . . 95 N·m (70 ft. lbs.)

Backing Plate Bolt . . . . . . . . . 614 N·m (45 ft. lbs.)

RWAL/ABS Sensor Bolt . . . . . . 24 N·m (18. ft. lbs.)

Service procedures. Removal and installation. Disassembly and assembly

Service procedures. Removal and installation. Disassembly and assembly

Other materials:

Lamp bulb service

REMOVAL AND INSTALLATIONHeadlamp bulb

REMOVAL

(1) Remove the screws attaching the bezel to the

grille opening panel (Fig. 1).

(2) Remove screws attaching the retaining ring to

the headlamp canister.

(3) Disconnect the headlamp bulb wire harness

connector.

(4) Separate the sealed beam fr ...