Jeep Cherokee (XJ): Front planetary gear. Sun gear and no. 1 one-way clutch. Second brake

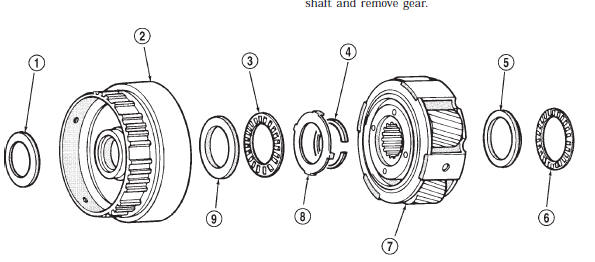

DISASSEMBLY (1) Remove ring gear from planetary gear (Fig. 268).

(2) Remove front bearing and the two races from

ring gear (Fig. 268).

1 - DIRECT CLUTCH (3) Remove tabbed thrust race from planetary gear

(Fig. 268).

(4) Remove snap ring attaching planetary gear to

shaft and remove gear.

1 - FORWARD RACE (5) Remove rear bearing and race from planetary gear.

(6) Measure inside diameter of ring gear bushing.

Maximum allowable diameter is 24.08 mm (0.9480

in.). Replace ring gear if bushing inside diameter is

greater than specified.

(7) Check condition of planetary gear. Replace gear

if teeth are worn, pins are loose, or carrier is cracked,

distorted, or worn. ASSEMBLY (1) Lubricate planetary and ring gear bearings and

races with petroleum jelly.

(2) Identify planetary bearings and races before

installation. (Fig. 268). Bearings and races can be

identified by following dimensions: (3) Install rear race and bearing in gear (Fig. 269).

(4) Turn planetary over and install thrust race

(Fig. 270).

(5) Install front race and bearing and forward race

in ring gear (Fig. 271).

1 - REAR BEARING AND RACE

1 - TABBED THRUST RACE

1 - FRONT BEARING AND RACE

1 - SNAP RING DISASSEMBLY (1) Hold sun gear and turn second brake hub

clockwise and counterclockwise (Fig. 272). Hub

should rotate freely clockwise but lock when turned

counterclockwise. Replace one-way clutch and hub if

they do not operate properly.

(2) Remove one-way clutch/second brake hub

assembly from drum (Fig. 273).

1 - SECOND BRAKE HUB

1 - HUB AND CLUTCH ASSEMBLY (3) Remove thrust washer from drum (Fig. 274).

1 - THRUST WASHER (4) Remove two seal rings from sun gear (Fig.

275).

1 - SEALS RINGS (2) (5) Support sun gear on wood block (Fig. 276).

Then remove first sun gear snap ring and separate

drum from gear.

1 - SUN GEAR (6) Remove remaining snap ring from sun gear

(Fig. 277).

1 - SUN GEAR (7) Measure inside diameter of sun gear bushings

with bore gauge or inside micrometer (Fig. 278).

Maximum allowable diameter is 27.08 mm (1.0661

in.). Replace sun gear if bushing inside diameter is

greater than specified.

1 - BORE GAUGE ASSEMBLY (1) Install first snap ring on sun gear.

(2) Install sun gear in drum and install remaining

snap ring.

(3) Coat replacement seal rings with petroleum

jelly and install them on sun gear. Be sure seal

ring ends are interlocked.

(4) Install thrust washer. Be sure washer tabs are

seated in drum slots.

1 - CLUTCH AND HUB ASSEMBLY (5) Install one-way clutch/second brake hub

assembly on sun gear. Deep side of hub flange faces

upward (Fig. 279).

1 - THRUST WASHER (6) Check one-way clutch operation again (Fig.

272). Hold sun gear and turn second brake hub clockwise

and counterclockwise. Hub should turn clockwise

freely, but lock when turned counterclockwise. DISASSEMBLY (1) Remove second brake drum from output shaft

(Fig. 280).

1 - SECOND BRAKE ASSEMBLY (2) Remove thrust washer from second brake drum

(Fig. 281).

(3) Compress piston return springs with shop

press and tool 7538. Then remove piston snap ring

(Fig. 282).

(4) Remove compressor tool and remove spring

retainer and return springs.

(5) Remove second brake piston and sleeve from

drum with compressed air (Fig. 283). Use only

enough air pressure to ease piston out of drum.

(6) Remove and discard brake piston O-rings.

(7) Measure free length of piston return springs

with springs mounted in retainer (Fig. 284). Length

should be approximately 16.05 mm (0.632 in.).

Replace return springs if length is less than specified.

1 - THRUST WASHER

1 - COMPRESSOR TOOL

1 - PISTON AND SLEEVE

1 - PISTON RETURN SPRINGS ASSEMBLY (1) Lubricate and install new O-rings on brake

piston. Then install brake piston in drum.

(2) Install return springs and retainer on brake

piston.

(3) Compress return springs with shop press and

Compressor Tool 7538. Install piston snap ring and

remove brake assembly from press.

(4) Check brake piston operation with low pressure

compressed air (Fig. 285). Apply air pressure

through feed hole in drum. Piston should move

smoothly when applying-releasing air pressure.

1 - PISTON (5) Coat thrust washer with petroleum jelly and

install it in drum. Be sure washer notches are

aligned with tabs on spring retainer (Fig. 286)

1 - THRUST WASHER NOTCHESFront planetary gear

Fig. 267 Checking Forward Clutch Assembled Height

2 - APPROXIMATELY 71.2 mm (2.80 in.)

3 - FORWARD CLUTCH

Fig. 268 Front Planetary Gear Components

2 - FRONT PLANETARY RING GEAR

3 - FRONT BEARING

4 - SNAP RING

5 - REAR RACE

6 - REAR BEARING

7 - FRONT PLANETARY GEAR

8 - THRUST RACE

9 - FRONT RACE

Fig. 269 Front Planetary Rear Bearing and Race Installation

2 - PLANETARY GEAR

Fig. 270 Front Planetary Thrust Race Installation

2 - PLANETARY GEAR

Fig. 271 Front Planetary Front Bearing And Races Installation

2 - FORWARD RACESun gear and no. 1 one-way clutch

Sun Gear And One-Way Clutch Components

2 - SUN GEAR

3 - SUN GEAR INPUT DRUM

4 - THRUST WASHER

5 - ONE-WAY CLUTCH AND SECOND BRAKE HUB ASSEMBLY

6 - SNAP RING

7 - SEAL RINGS

Fig. 272 Checking One-Way Clutch Operation

2 - SUN GEAR

Fig. 273 Removing/Installing Brake Hub And Clutch Assembly

2 - DRUM

Fig. 274 Removing/Installing Thrust Washer

Fig. 275 Removing/Installing Sun Gear Seal Rings

Fig. 276 Removing/Installing Sun Gear

2 - SNAP RING

3 - WOOD BLOCK

4 - INPUT DRUM

Fig. 277 Removing/Installing Second Snap Ring

2 - SECOND SNAP RING

Fig. 278 Checking Sun Gear Bushings

Fig. 279 Installing Clutch And Hub Assembly On

Sun Gear

Second Brake Components

2 - SNAP RING

3 - SPRING RETAINER

4 - PISTON RETURN SPRINGS

5 - REAR PLANETARY/OUTPUT SHAFT/FIRST-REVERSE

BRAKE

6 - SECOND BRAKE DRUM

7 - O-RINGS

8 - SECOND BRAKE PISTON

9 - PISTON SLEEVESecond brake

Fig. 280 Removing/Installing Second Brake Assembly

2 - OUTPUT SHAFT

Fig. 281 Removing/Installing Second Brake Drum Thrust Washer

2 - SECOND BRAKE DRUM

Fig. 282 Removing/Installing Second Brake Piston Snap Ring

2 - PISTON SNAP RING

Fig. 283 Removing/Installing Piston And Sleeve

2 - DRUM

Fig. 284 Measuring Second Brake Piston Return Springs

2 - SPRING RETAINER

Fig. 285 Checking Second Brake Piston Operation

2 - DRUM

Fig. 286 Installing Second Brake Thrust Washer

2 - SPRING RETAINER TABS

Planetary/brake pack/output shaft

Planetary/brake pack/output shaft

Other materials:

Event Data Recorder (EDR)

This vehicle is equipped with an event data recorder

(EDR). The main purpose of an EDR is to record, in

certain crash or near crash-like situations, such as an air

bag deployment or hitting a road obstacle, data that will

assist in understanding how a vehicle's systems performed.

The EDR is d ...