Jeep Cherokee (KL): Wheel and tire torque specifications

Proper lug nut/bolt torque is very important to ensure that the wheel is properly mounted to the vehicle. Any time a wheel has been removed and reinstalled on the vehicle the lug nuts/bolts should be torqued using a properly calibrated torque wrench.

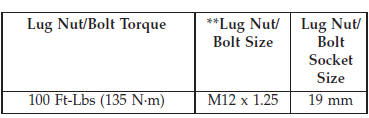

Torque specifications

**Use only your Authorized Dealer recommended lug nuts/bolts and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to mounting the tire and remove any corrosion or loose particles.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until each nut/bolt has been tightened twice.

Torque Patterns

After 25 miles (40 km) check the lug nut/bolt torque to be sure that all the lug nuts/bolts are properly seated against the wheel.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do not tighten the lug nuts fully until the vehicle has been lowered. Failure to follow this warning may result in personal injury.

Other materials:

Removal and installation

Horn relay

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse access panel by unsnapping it

from the right cowl side inner trim panel (Fig. 3).

(3) Remove the push nut that secures the right

cowl side inner trim panel to the junction block stud.

(4) Remov ...