Jeep Cherokee (XJ): Alignment

WHEEL ALIGNMENT DESCRIPTION Wheel alignment involves the correct positioning of

the wheels in relation to the vehicle. The positioning

is accomplished through suspension and steering

linkage adjustments. An alignment is considered

essential for efficient steering, good directional stability

and to minimize tire wear. The most important

measurements of an alignment are caster, camber

and toe position (Fig. 1).

CAUTION: Never attempt to modify suspension or

steering components by heating or bending.

CAUTION: Components attached with a nut and

cotter pin must be torqued to specification. Then if

the slot in the nut does not line up with the cotter

pin hole, tighten nut until it is aligned. Never loosen

the nut to align the cotter pin hole.

NOTE: Periodic lubrication of the front suspension/

steering system components may be required. Rubber

bushings must never be lubricated. Refer to

Group 0, Lubrication And Maintenance for the recommended

maintenance schedule. OPERATION

1 - WHEEL CENTERLINE SUSPENSION AND STEERING SYSTEM CONDITION POSSIBLE CAUSES CORRECTION PRE-ALIGNMENT Before starting wheel alignment, the following

inspection and necessary corrections must be completed.

Refer to Suspension and Steering System

Diagnosis Chart for additional information. WHEEL ALIGNMENT Before each alignment reading, the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down several times. Always release the bumper in

the down position. Set the front end alignment to

specifications with the vehicle at its NORMAL RIDE

HEIGHT. CAMBER The wheel camber angle is preset. This angle is not

adjustable and cannot be altered. CASTER Before checking the caster of the front axle for correct

angle, be sure the axle is not bent or twisted.

Road test the vehicle, make left and right turns. If

the steering wheel returns to the center position

unassisted, the caster angle is correct. If steering

wheel does not return toward the center position

unassisted, an incorrect caster angle is probable.

Caster can be adjusted by installing the appropriate

size shims (Fig. 2). NOTE: Changing caster angle will also change the

front propeller shaft angle. The propeller shaft

angle has priority over caster. Refer to Group 3 Differential

& Driveline for additional information.

1 - SHIM TOE POSITION (LHD) NOTE: The wheel toe position adjustment is the

final adjustment. The engine must remain running

during the entire toe position adjustment. NOTE: Once the toe setting is correct, the steering

wheel can be re-centered by adjusting only the drag

link. TOE POSITION (RHD) NOTE: The wheel toe position adjustment is the

final adjustment. The engine must remain running

during the entire toe position adjustment.

1 - PITMAN ARM

1 - PITMAN ARM NOTE: Make sure the toe setting does not change

during clamp tightening. NOTE: Make sure the toe setting does not change

during clamp tightening. NOTE: Once the toe setting is correct, the steering

wheel can be re-centered by adjusting only the drag

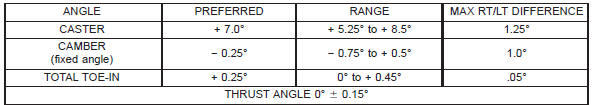

link. ALIGNMENT NOTE: All alignment specifications are in degrees.

Description and operation

Fig. 1 Wheel Alignment Measurements

2 - NEGATIVE CAMBER ANGLE

3 - PIVOT CENTERLINE

4 - SCRUB RADIUS

5 - TRUE VERTICAL

6 - KING PIN

7 - VERTICAL

8 - POSITIVE CASTERDiagnosis and testing

FRONT END NOISE

EXCESSIVE PLAY IN

STEERING

FRONT WHEELS SHIMMY

VEHICLE INSTABILITY

EXCESSIVE STEERING

EFFORT

VEHICLE PULLS TO ONE

SIDE DURING BRAKING

VEHICLE LEADS OR

DRIFTS FROM STRAIGHT

AHEAD DIRECTION ON

UNCROWNED ROAD

KNOCKING, RATTLING

OR SQUEAKING

IMPROPER TRACKING

Service procedures

Fig. 2 Caster Adjustment

2 - SUSPENSION ARM

Fig. 4 Drag Link and Tie Rod Clamp (LHD)

Fig. 3 Steering Linkage (LHD)

2 - ADJUSTMENT SLEEVE

3 - DRAG LINK

4 - TIE ROD

5 - STEERING DAMPENER

Fig. 5 Steering Linkage (RHD)

2 - DRAG LINK

3 - STEERING DAMPNER

4 - TIE ROD

5 - ADJUSTMENT SLEEVE

Specifications

Other materials:

Headlight Time Delay. Automatic High Beam Headlamp Control. Daytime Running Lights (DRL)

Headlight Time Delay

This feature provides the safety of headlight illumination

for up to 90 seconds (programmable) when leaving your

vehicle in an unlit area.

To activate the delay feature, place the ignition in the OFF

position while the headlights are still on. Then, turn off

the headlight ...