Jeep Cherokee (XJ): Description and operation. Diagnosis and testing. Removal and installation

DESCRIPTION The NV231 is a part-time transfer case with a low

range reduction gear system. The NV231 has three

operating ranges plus a Neutral position. A low range

system provides a reduction ratio for increased low

speed torque capability.

The geartrain is mounted in two aluminum case

halves attached with bolts. The mainshaft front and

rear bearings are mounted in aluminum retainer

housings bolted to the case halves. OPERATING RANGES Transfer case operating ranges are: The 2WD range is for use on any road surface at

any time.

The 4x4 and 4 Lo ranges are for off road use only.

They are not for use on hard surface roads. The only

exception being when the road surface is wet or slippery

or covered by ice and snow.

The low range reduction gear system is operative

in 4 Lo range only. This range is for extra pulling

power in off road situations. Low range reduction

ratio is 2.72:1. SHIFT MECHANISM Operating ranges are selected with a floor mounted

shift lever. The shift lever is connected to the transfer

case range lever by an adjustable linkage rod. A

straight line shift pattern is used. Range positions

are marked on the shifter bezel cover plate. IDENTIFICATION A circular ID tag is attached to the rear case of

each transfer case (Fig. 1). The ID tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.

The transfer case serial number also represents

the date of build.

1 - I. D. TAG OPERATION The input gear is splined to the transmission output

shaft. The input gear drives the mainshaft

through the planetary assembly and range hub. The

front output shaft is operated by a drive chain that

connects the shaft to a drive sprocket on the mainshaft.

The drive sprocket is engaged/disengaged by

the mode fork, which operates the mode sleeve and hub. The sleeve and hub are

not equipped with a

synchronizer mechanism for shifting. DESCRIPTION Recommended lubricant for the NV231 transfer

case is Mopart Dexron II, or ATF Plus 3, type 7176.

Approximate lubricant fill capacity is 1.2 liters (2.5

pints).

The fill and drain plugs are both in the rear case

(Fig. 2). Correct fill level is to the bottom edge of the

fill plug hole. Be sure the vehicle is level to ensure

an accurate fluid level check.

1 - I. D. TAG NV231 DIAGNOSIS DIAGNOSIS CHART Condition Possible Cause Correction REMOVAL (1) Shift transfer case into Neutral.

(2) Raise vehicle.

(3) Drain transfer case lubricant.

(4) Mark front and rear propeller shaft yokes for

alignment reference.

(5) Support transmission with jack stand.

(6) Remove rear crossmember, or skid plate.

(7) Disconnect front/rear propeller shafts at transfer

case.

(8) Disconnect vehicle speed sensor wires.

(9) Disconnect transfer case linkage rod from

range lever.

(10) Disconnect transfer case vent hose (Fig. 3)

and indicator switch harness, if necessary.

(11) Support transfer case with transmission jack.

(12) Secure transfer case to jack with chains.

(13) Remove nuts attaching transfer case to transmission.

(14) Pull transfer case and jack rearward to disengage

transfer case.

(15) Remove transfer case from under vehicle. INSTALLATION (1) Mount transfer case on a transmission jack.

(2) Secure transfer case to jack with chains.

1 - VENT TUBE (3) Position transfer case under vehicle.

(4) Align transfer case and transmission shafts

and install transfer case on transmission.

(5) Install and tighten transfer case attaching nuts

to 35 N·m (26 ft. lbs.) torque (Fig. 3).

(6) Connect vehicle speed sensor wires, and vent

hose.

(7) Connect indicator switch harness to transfer

case switch, if necessary. Secure wire harness to clips

on transfer case. (8) Align and connect propeller shafts. Refer to

Group 3, Differential and Driveline, for proper procedures

and specifications.

(9) Fill transfer case with correct fluid. Check

transmission fluid level. Correct as necessary.

(10) Install rear crossmember, or skid plate.

Tighten crossmember bolts to 41 N·m (30 ft. lbs.)

torque.

(11) Remove transmission jack and support stand.

(12) Connect shift rod to transfer case range lever.

(13) Adjust transfer case shift linkage.

(14) Lower vehicle and verify transfer case shift

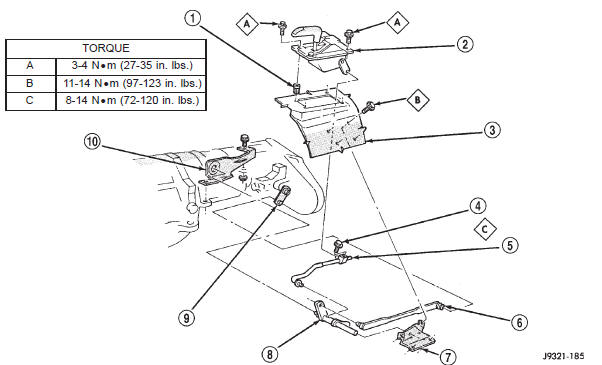

operation. REMOVAL (1) Shift transfer case into 4L.

(2) Raise vehicle.

(3) Loosen adjusting trunnion locknut and slide

shift rod out of trunnion (Fig. 4). If rod lacks enough

travel to come out of trunnion, push trunnion out of

torque shaft.

(4) Lower vehicle.

(5) Remove console. Refer to Group 23, Body, for

proper procedures.

(6) Remove screws attaching lever assembly to

floorpan and remove assembly and shift rod (if left

attached). INSTALLATION (1) If shift rod was not removed from lever assembly,

work rod down through floorpan opening. Then

position lever assembly on floorpan and install

assembly attaching screws.

(2) Install console. Refer to Group 23, Body, for

proper procedures.

(3) Raise vehicle.

(4) Connect trunnion to torque shaft arm. Or, slide

shift rod into trunnion on range lever. Be sure shift

rod slides freely in trunnion.

(5) Verify that range lever is in 4L position. Then

tighten trunnion lock bolt.

1 - RIVNUT (4) (6) Lower vehicle and check transfer case shift

operation. REMOVAL (1) Raise vehicle.

(2) Disconnect wires from vehicle speed sensor.

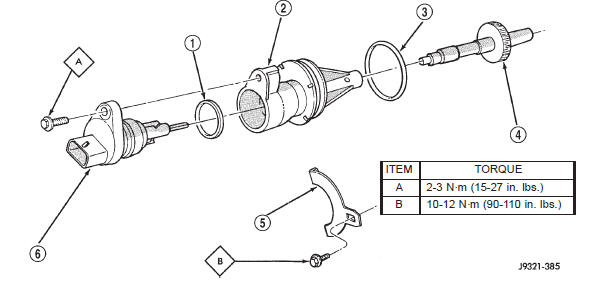

(3) Remove adapter clamp and screw (Fig. 5).

(4) Remove speed sensor and speedometer adapter

as an assembly.

(5) Remove speed sensor retaining screw and

remove sensor from adapter.

(6) Remove speedometer pinion from adapter.

Replace pinion if chipped, cracked, or worn.

(7) Inspect sensor and adapter O-rings (Fig. 5).

Remove and discard O-rings if worn or damaged.

(8) Inspect terminal pins in speed sensor. Clean

pins with Mopart electrical spray cleaner if dirty or

oxidized. Replace sensor if faulty, or if pins are loose,

severely corroded, or damaged. INSTALLATION AND INDEXING (1) Thoroughly clean adapter flange and adapter

mounting surface in housing. Surfaces must be clean

for proper adapter alignment and speedometer operation.

(2) Install new O-rings on speed sensor and speedometer

adapter (Fig. 5), if necessary.

(3) Lubricate sensor and adapter O-rings with

transmission fluid.

(4) Install vehicle speed sensor in speedometer

adapter. Tighten sensor attaching screw to 2-3 N·m

(15-27 in. lbs.) torque.

(5) Install speedometer pinion in adapter.

(6) Count number of teeth on speedometer pinion.

Do this before installing assembly in housing. Then

lubricate pinion teeth with transmission fluid.

(7) Note index numbers on adapter body (Fig. 6).

These numbers will correspond to number of teeth on

pinion.

(8) Install speedometer assembly in housing.

(9) Rotate adapter until required range numbers

are at 6 o-clock position. Be sure range index numbers

correspond to number of teeth on pinion gear.

(10) Install speedometer adapter clamp and retaining

screw. Tighten clamp screw to 10-12 N·m (90-110

in. lbs.) torque.

(11) Connect wires to vehicle speed sensor.

(12) Lower vehicle and top off transmission fluid

level if necessary. REMOVAL (1) Raise vehicle.

(2) Remove front propeller shaft. Refer to Group 3,

Differential and Driveline, for proper procedure.

1 - SENSOR O-RING

1 - SPEEDOMETER ADAPTER (3) Remove front output shaft yoke.

(4) Remove seal from front case with pry tool (Fig.

7).

1 - OUTPUT SHAFT SEAL INSTALLATION (1) Install new front output seal in front case with

Installer Tool 8143 as follows:

(a) Place new seal on tool. Garter spring on seal

goes toward interior of case.

(b) Start seal in bore with light taps from hammer

(Fig. 8). Once seal is started, continue tapping

seal into bore until installer tool seats against case.

1 - INSTALLER 8143Description and operation

NV231 transfer case

Fig. 1 Fill/Drain Plug And I. D. Tag Locations

2 - FILL PLUG

3 - DRAIN PLUGLubricant and fill level

Fig. 2 Fill/Drain Plug Locations

2 - FILL PLUG

3 - DRAIN PLUGDiagnosis and testing

Transfer case difficult to shift or will

not shift into desired range.

Transfer case noisy in all drive

modes.

Transfer case noisy while in, or

jumps out of, 4L mode.

Lubricant leaking from transfer case

seals or vent.

Abnormal tire wear.

Removal and installation

Transfer case

Fig. 3 Transfer Case Mounting

2 - TRANSFER CASE

3 - TRANSMISSIONShift lever

Fig. 4 Shift Linkage

2 - SHIFT LEVER ASSEMBLY

3 - FLOORPAN

4 - TRUNNION LOCK BOLT

5 - SELECTOR ROD AND TRUNNION

6 - SHIFT LEVER ROD

7 - TORQUE SHAFT FRAME BRACKET

8 - TORQUE SHAFT

9 - TRANSFER CASE SHIFT LEVER

10 - TORQUE SHAFT TRANSFER CASE BRACKETSpeedometer

Front output shaft seal

Fig. 5 Speedometer Components

2 - SPEEDOMETER ADAPTER

3 - ADAPTER O-RING

4 - SPEEDOMETER PINION

5 - ADAPTER CLAMP

6 - VEHICLE SPEED SENSOR

Fig. 6 Location Of Index Numbers On Speedometer Adapter

2 - INDEX NUMBER LOCATION

Fig. 7 Remove Front Output Shaft Seal

2 - PRYBAR

Fig. 8 Front Output Seal Installation

2 - TRANSFER CASE

Other materials:

Towing Tips

Before setting out on a trip, practice turning, stopping,

and backing the trailer in an area located away from

heavy traffic.

Automatic Transmission

The DRIVE range can be selected when towing. The

transmission controls include a drive strategy to avoid

frequent shifting when towing. However, ...