Jeep Cherokee (XJ): Tires

DESCRIPTION Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling characteristics

match the vehicle's requirements. With

proper care they will give excellent reliability, traction,

skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain in most

cases, much greater mileage than severe use or careless

drivers. A few of the driving habits which will

shorten the life of any tire are: Radial-ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation interval

shown in the section on Tire Rotation. This will

help to achieve a greater tread life. TIRE IDENTIFICATION Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 1).

Performance tires have a speed rating letter after

the aspect ratio number.

The speed rating is not always printed on the tire

sidewall.

TIRE CHAINS Tire snow chains may be used on certain models.

Refer to the Owner's Manual for more information. DESCRIPTION Radial-ply tires improve handling, tread life and

ride quality, and decrease rolling resistance.

Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary

spare tires when necessary. A maximum speed of 50

MPH is recommended while a temporary spare is in

use.

Radial-ply tires have the same load-carrying capacity

as other types of tires of the same size. They also

use the same recommended inflation pressures.

The use of oversized tires, either in the front or

rear of the vehicle, can cause vehicle drive train failure.

This could also cause inaccurate wheel speed

signals when the vehicle is equipped with Anti-Lock

Brakes.

The use of tires from different manufactures on the

same vehicle is NOT recommended. The proper tire

pressure should be maintained on all four tires. DESCRIPTION The temporary spare tire is designed for emergency

use only. The original tire should be repaired

or replaced at the first opportunity, then reinstalled.

Do not exceed speeds of 50 M. P. H. when using the

temporary spare tire. Refer to Owner's Manual for

complete details. Under inflation will cause rapid shoulder wear, tire

flexing, and possible tire failure (Fig. 2).

1 - THIN TIRE THREAD AREAS Over inflation will cause rapid center wear and

loss of the tire's ability to cushion shocks (Fig. 3).

1 - THIN TIRE THREAD AREA Improper inflation can cause: For proper tire pressure specification refer to the

Tire Inflation Pressure Chart provided with the vehicle.

Tire pressures have been chosen to provide safe

operation, vehicle stability, and a smooth ride. Tire

pressure should be checked cold once a month. The

spare tire pressure should be check at least twice

annually. Tire pressure decreases as the ambient

temperature drops. Check tire pressure frequently

when ambient temperature varies widely.

Inflation pressures specified on the placards are

cold inflation pressure. The vehicle must sit for at

least 3 hours to obtain the correct cold inflation pressure

reading. Or driven less than one mile after sitting

for 3 hours. Tire inflation pressures may

increase from 2 to 6 pounds per square inch (psi)

during operation, due to increased tire temperature.

WARNING: OVER OR UNDER INFLATED TIRES

CAN AFFECT VEHICLE HANDLING AND TREAD

WEAR. THIS MAY CAUSE THE TIRE TO FAIL SUDDENLY,

RESULTING IN LOSS OF VEHICLE CONTROL. DESCRIPTION Where speed limits allow the vehicle to be driven

at high speeds, correct tire inflation pressure is very

important. For speeds up to and including 120 km/h

(75 mph), tires must be inflated to the pressures

shown on the tire placard. For continuous speeds in

excess of 120 km/h (75 mph), tires must be inflated

to the maximum pressure specified on the tire sidewall.

Vehicles loaded to the maximum capacity should

not be driven at continuous speeds above 75 mph

(120 km/h).

For emergency vehicles that are driven at speeds

over 90 mph (144 km/h), special high speed tires

must be used. Consult tire manufacturer for correct

inflation pressure recommendations. DESCRIPTION The original equipment tires provide a proper balance

of many characteristics such as: It is recommended that tires equivalent to the original

equipment tires be used when replacement is

needed.

Failure to use equivalent replacement tires may

adversely affect the safety and handling of the vehicle.

The use of oversize tires may cause interference

with vehicle components. Under extremes of suspension

and steering travel, interference with vehicle

components may cause tire damage.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED CAPABILITY

CAN RESULT IN SUDDEN TIRE FAILURE. Pressure gauges A quality air pressure gauge is recommended to

check tire pressure. After checking the air pressure,

replace valve cap finger tight. Tread wear indicators Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 4).

Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs. Tire wear patterns Under inflation will cause wear on the shoulders of

tire. Over inflation will cause wear at the center of

tire.

Excessive camber causes the tire to run at an

angle to the road. One side of tread is then worn

more than the other (Fig. 5).

Excessive toe-in or toe-out causes wear on the

tread edges and a feathered effect across the tread

(Fig. 5). Tire noise or vibration Radial-ply tires are sensitive to force impulses

caused by improper mounting, vibration, wheel

defects, or possibly tire imbalance.

To find out if tires are causing the noise or vibration,

drive the vehicle over a smooth road at varying speeds. Note the noise level

during acceleration,

deceleration and slight left and right steering inputs.

1 - THREAD ACCEPTABLE ROTATION Tires on the front and rear operate at different

loads and perform different steering, driving, and

braking functions. For these reasons they wear at

unequal rates and tend to develop irregular wear

patterns. These effects can be reduced by rotating

the tires at regular intervals. The benefits of tire

rotation are: The suggested method of tire rotation is (Fig. 6).

Other rotation methods can be used, but they will

not provide all the tire longevity benefits.

Tires and wheels are currently match mounted at

the factory. Match mounting is a technique used to

reduce runout in the wheel/tire assembly. This means

that the high spot of the tire is aligned with the low

spot on the wheel rim. The high spot on the tire is

marked with a paint mark or a bright colored adhesive

label on the outboard sidewall. The low spot on

the rim is identified with a label on the outside of the

rim and a dot on the inside of the rim. If the outside

label has been removed the tire will have to be

removed to locate the dot on the inside of the rim.

Before dismounting a tire from its wheel, a reference

mark should be placed on the tire at the valve

stem location. This reference will ensure that it is

remounted in the original position on the wheel.

(1) Use a dial indicator to locate the high spot of

the tire on the center tread rib (Fig. 7). Record the

indicator reading and mark the high spot on the tire.

Place a mark on the tire at the valve stem location

(Fig. 8).

1 - REFERENCE MARK (2) Break down the tire and remount it 180

degrees on the rim (Fig. 9).

Fig. 9 Remount Tire 180 Degrees 1 - VALVE STEM (3) Measure the total runout again and mark the

tire to indicate the high spot.

(4) If runout is still excessive use the following

procedures.

(a) If the high spot is within 101.6 mm (4.0 in.)

of the first spot and is still excessive, replace the

tire.

(b) If the high spot is within 101.6 mm (4.0 in.)

of the first spot on the wheel, the wheel may be out

of specifications. Refer to Wheel and Tire Runout.

(c) If the high spot is NOT within 101.6 mm (4.0

in.) of either high spot, draw an arrow on the tread

from second high spot to first. Break down the tire

and remount it 90 degrees on rim in that direction

(Fig. 10). This procedure will normally reduce the

runout to an acceptable amount. For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 11). The

tire should be replaced if the puncture is located in

the sidewall.

1 - 2ND HIGH SPOT ON TIRE Deflate tire completely before removing the tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges which could damage

the tire or wheel rim.

Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if necessary.

Install wheel on vehicle, and tighten to proper

torque specification. CLEANING TIRES Remove the protective coating on the tires before

delivery of a vehicle. This coating may cause deterioration

of the tires.

1 - REPAIRABLE AREA To remove the protective coating, apply warm

water and let it soak for a few minutes. Afterwards,

scrub the coating away with a soft bristle brush.

Steam cleaning may also be used to remove the coating.

NOTE: DO NOT use gasoline, mineral oil, oil-based

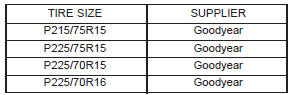

solvent or a wire brush for cleaning. TIRE SIZEDescription and operation

Tires

Fig. 1 Tire IdentificationRadial-ply tires

Spare tire-temporary

Tire inflation pressures

Fig. 2 Under Inflation Wear

Fig. 3 Over Inflation Wear

Tire pressure for high speed

Replacement tires

Diagnosis and testing

Fig. 4 Tread Wear Indicators

2 - THREAD UNACCEPTABLE

3 - WEAR INDICATORService procedures

Rotation

Fig. 6 Tire Rotation PatternMatch mounting

Fig. 5 Tire Wear Patterns

Fig. 7 Dial Indicator

Fig. 8 First Measurement On Tire

2 - 1ST MEASUREMENT

HIGH SPOT MARK TIRE AND RIM

3 - WHEEL

4 - VALVE STEM

2 - REFERENCE MARKRepairing leaks

Fig. 10 Remount Tire 90 Degrees In Direction of Arrow

2 - 1ST HIGH SPOT ON TIRECleaning and inspection

Fig. 11 Tire Repair AreaSpecifications

Other materials:

Cleaning and inspection

STARTING SYSTEM

The following components of the starting system

should be carefully inspected whenever any starting

system problem is encountered.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL ...