Jeep Cherokee (XJ): Diagnosis and testing

For circuit descriptions and diagrams, refer to

8W-60 - Power Windows in Group 8W - Wiring Diagrams. ALL WINDOWS INOPERATIVE (1) Check the circuit breaker in the junction block,

as described in this group. If OK, go to Step 2. If not

OK, replace the faulty circuit breaker.

(2) Disconnect and isolate the battery negative

cable. Remove the driver side front door trim panel

and unplug the Driver Door Module (DDM) wire harness

connectors from the DDM. Check for continuity

between the ground circuit cavity of the 8-way DDM

wire harness connector and a good ground. If OK, go

to Step 3. If not OK, repair the circuit to ground as

required.

(3) Connect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the master switch power feed (run/acc) circuit

cavity of the 12-way DDM wire harness connector.

If OK, see the diagnosis for the Door Module in

this group. If not OK, repair the open circuit to the

circuit breaker in the junction block as required. ONE WINDOW INOPERATIVE The window glass must be free to slide up and

down for the power window motor to function properly.

If the glass is not free to move up and down, the

motor will overload and trip the integral circuit

breaker. To determine if the glass is free, disconnect

the regulator plate from the glass. Then slide the

window up and down by hand.

There is an alternate method to check if the glass

is free. Position the glass between the up and down

stops. Then, shake the glass in the door. Check that the glass can be moved

slightly from side to side,

front to rear, and up and down. Then check that the

glass is not bound tight in the tracks. If the glass is

free, proceed with the diagnosis that follows. If the

glass is not free, refer to Group 23 - Body for the

door window glass and hardware service and adjustment

procedures.

(1) Check the power window switch continuity as

described in the diagnosis for the Door Module (front

doors) or Power Window Switch (rear doors) in this

group. If OK and the driver side front window is

inoperative, see the Power Window Motor diagnosis

in this group. If OK and the inoperative window is

other than the driver side front, go to Step 2. If not

OK, replace the faulty door module or switch.

(2) Refer to the circuit diagrams in 8W-60 - Power

Windows in Group 8W - Wiring Diagrams. Check the

continuity in each circuit between the inoperative

Passenger Door Module (PDM) or power window

switch wire harness connector cavities and the corresponding

Driver Door Module (DDM) wire harness

connector cavities. If OK, see the diagnosis for the

Power Window Motor in this group. If not OK, repair

the open circuit(s) as required.

NOTE: All individual power window switches

receive their battery and ground feeds through the

Driver Door Module (DDM) and wire harness connectors. For circuit descriptions and diagrams, refer to

8W-60 - Power Windows in Group 8W - Wiring Diagrams.

(1) Locate the circuit breaker in the junction block.

Pull out the circuit breaker slightly, but be certain

that the circuit breaker terminals still contact the

terminals in the junction block cavities.

(2) Connect the negative lead of a 12-volt DC voltmeter

to a good ground.

(3) With the voltmeter positive lead, check both

terminals of the circuit breaker for battery voltage.

If only one terminal has battery voltage, the circuit

breaker is faulty and must be replaced. If neither terminal

has battery voltage, repair the open circuit

from the Power Distribution Center (PDC) as

required. If the circuit breaker checks OK, but no

power windows operate, see Power Window System

in the Diagnosis and Testing section of this group. The Driver Door Module (DDM) contains the master

switches and the lockout switch in the power window

system. The DDM also contains an integrated

circuit to support the one-touch down feature of the

driver side front door power window. Remember that

the passenger side front door power window switch

and, on four-door models, the rear door power window

switches get their battery current through the

power window lockout switch in the Driver Door

Module (DDM). In addition, each individual power

window switch gets its ground through the master

switch in the DDM.

The one-touch down feature circuitry within the

DDM will not operate the power window motor if the

door glass, window regulator, or gearbox mechanism

are stuck, obstructed, or binding. If the driver side

front door power window operates as designed, but

the one-touch down feature is inoperative, replace

the faulty DDM.

If the problem being diagnosed is an inoperative

power window switch illumination lamp, but the

power window switch operates as designed, replace

the faulty door module. For circuit descriptions and

diagrams, refer to 8W-60 - Power Windows in Group

8W - Wiring Diagrams.

(1) Disconnect and isolate the battery negative

cable. Remove the front door trim panel and unplug

the door module wire harness connectors from the

door module.

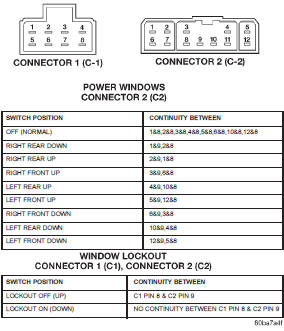

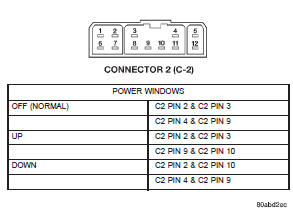

(2) Check the door module power window switch

and/or power window lockout switch continuity in

each position, as shown in the proper chart (Fig. 1)

or (Fig. 2). If OK, see the Power Window Motor diagnosis

in this group. If not OK, replace the faulty door

module.

The diagnosis found here applies only to the rear

door power window switches. For diagnosis of the

front door power window switches, see Door Module

in this group. If the problem being diagnosed is an

inoperative power window switch illumination lamp,

but the power window switch operates as designed,

replace the faulty switch. For circuit descriptions and

diagrams, refer to 8W-60 - Power Windows in Group

8W - Wiring Diagrams.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the power window switch from the

rear door trim panel.

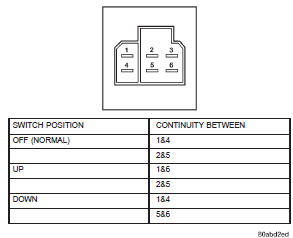

(3) Check the power window switch continuity in

each position as shown in the Rear Door Power Window

Switch Continuity chart (Fig. 3). If OK, see the

Power Window Motor diagnosis in this group. If not

OK, replace the faulty switch.

For circuit descriptions and diagrams, refer to

8W-60 - Power Windows in Group 8W - Wiring Diagrams.

Before you proceed with this diagnosis, confirm

proper switch operation. See the Door Module

and/or Power Window Switch diagnosis in this group.

(1) Disconnect and isolate the battery negative

cable. Remove the trim panel from the door with the

inoperative power window.

(2) Unplug the power window motor wire harness

connector. Apply 12 volts across the motor terminals

to check its operation in one direction. Reverse the

connections across the motor terminals to check the

operation in the other direction. Remember, if the

window is in the full up or full down position, the

motor will not operate in that direction by design. If

OK, repair the circuits from the power window motor

to the door module or the power window switch as

required. If not OK, replace the faulty motor.

(3) If the motor operates in both directions, check

the operation of the window glass and lift mechanism

through its complete up and down travel. There

should be no binding or sticking of the window glass

or lift mechanism through the entire travel range. If

not OK, refer to Group 23 - Body to check the window

glass, tracks, and regulator for sticking, binding,

or improper adjustment.Power window system

Circuit breaker

Door module

Fig. 1 DDM Power Window Switch Continuity

Fig. 2 PDM Power Window Switch ContinuityPower window switch

Fig. 3 Rear Door Power Window Switch ContinuityPower window motor

Other materials:

Lamp bulb service

REMOVAL AND INSTALLATIONHeadlamp bulb

REMOVAL

(1) Remove the screws attaching the bezel to the

grille opening panel (Fig. 1).

(2) Remove screws attaching the retaining ring to

the headlamp canister.

(3) Disconnect the headlamp bulb wire harness

connector.

(4) Separate the sealed beam fr ...