Jeep Cherokee (XJ): Disassembly and assembly. Cleaning and inspection. Specifications

CYLINDER BLOCK DISASSEMBLY (1) Drain the engine oil. Remove and discard the

oil filter.

(2) Remove the water pump from the cylinder

block.

(3) Remove the distributor from the cylinder block.

(4) Remove the vibration damper.

(5) Remove the timing case cover and lay the cover

upside down.

(6) Position a drift punch into the slot in the back

of the cover and tap the old seal out.

(7) Remove the timing chain bumper.

(8) Remove the oil slinger from crankshaft.

(9) Remove the camshaft retaining bolt and

remove the sprockets and chain as an assembly.

(10) Remove the camshaft.

(11) Remove the oil pan and gasket.

(12) Remove the timing chain tensioner.

(13) Remove the front and rear oil galley plugs.

(14) Remove the connecting rods and the pistons.

Remove the connecting rod and piston assemblies

through the top of the cylinder bores.

(15) Remove the crankshaft. ASSEMBLY (1) Install the crankshaft.

(2) Install the connecting rods and the pistons

through the top of the cylinder bores.

(3) Install the front and rear oil galley plugs.

(4) Install the timing chain tensioner.

(5) Install the camshaft.

(6) Install the sprockets and chain as an assembly.

(7) Install the oil slinger to the crankshaft.

(8) Install the timing chain bumper.

(9) Install the timing case cover seal.

(10) Install the timing case cover.

(11) Install the oil pan gasket and oil pan.

(12) Install the vibration damper.

(13) Install the water pump. Tighten the mounting

bolts to 31 N·m (270 in. lbs.) torque.

(14) Remove the distributor from the cylinder

block.

(15) Lubricate the oil filter seal with clean engine

oil. Tighten oil filter to 18 N·m (13 ft. lbs.) torque.

(16) Install the engine into the vehicle.

(17) Fill the engine with clean lubrication oil.

(18) Fill the cooling system. CLEANING Clean all the components with cleaning solvent.

Use compressed air to blow out the oil passages in

the rocker arms and push rods. INSPECTION Inspect the pivot surface area of each rocker arm.

Replace any that are scuffed, pitted, cracked or

excessively worn Inspect the valve stem tip contact surface of each rocker

arm and replace any rocker arm that is deeply pitted.

Inspect each push rod end for excessive wear and

replace as required. If any push rod is excessively

worn because of lack of oil, replace it and inspect the

corresponding hydraulic tappet for excessive wear.

Inspect the push rods for straightness by rolling

them on a flat surface or by shining a light between

the push rod and the flat surface.

A wear pattern along the length of the push rod is

not normal. Inspect the engine cylinder head for

obstruction if this condition exists. CLEANING Thoroughly clean the engine cylinder head and cylinder

block mating surfaces. Clean the intake and

exhaust manifold and engine cylinder head mating

surfaces. Remove all gasket material and carbon.

Check to ensure that no coolant or foreign material

has fallen into the tappet bore area.

Remove the carbon deposits from the combustion

chambers and top of the pistons. INSPECTION Use a straightedge and feeler gauge to check the

flatness of the engine cylinder head and block mating

surfaces. CLEANING Thoroughly clean the oil pan and engine block gasket

surfaces.

Use compressed air to clean out: Once the block has been completely cleaned, apply

Mopart Thread Sealant with Teflon to the threads of

the front and rear oil galley plugs. Tighten the plugs

to 41 N·m (30 ft. lbs.) torque. INSPECTION Inspect the cylinder bores for signs of scorring, pitting

or cracks. If the cylinder bores are scorred or

pitted the cylinder bores will require boreing or honing

to clean them up. Refer to Honing Cylinder Bores

in this Section. If the cylinder bore(s) are cracked the

cylinder block must be replaced.

Inspect the cylinder block to cylinder head mating

surface for flatness and/or pitting.

1 - FILTER BYPASS HOLE

1 - FRONT OIL GALLEY HOLE

Fig. 91 Rear Oil Galley Hole 1 - REAR OIL GALLEY HOLE ENGINE DESCRIPTION

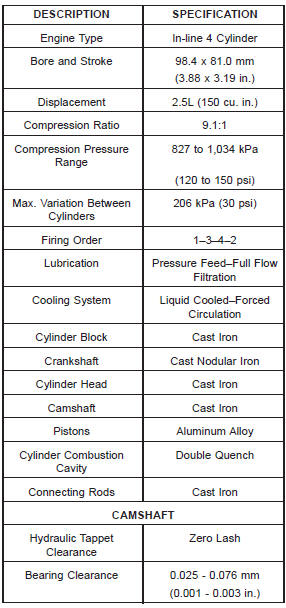

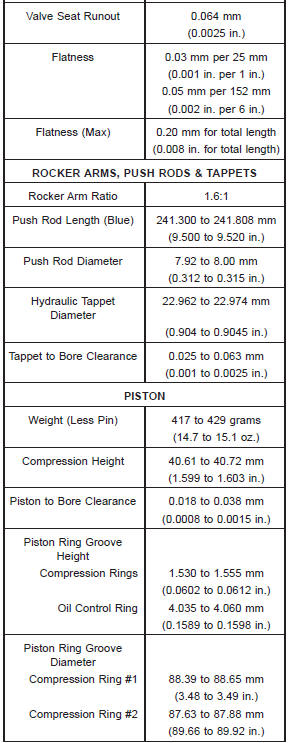

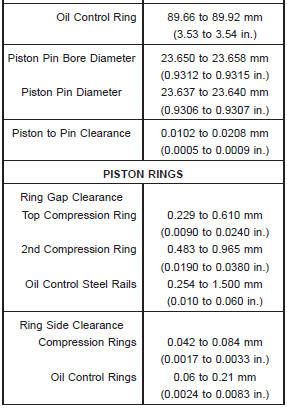

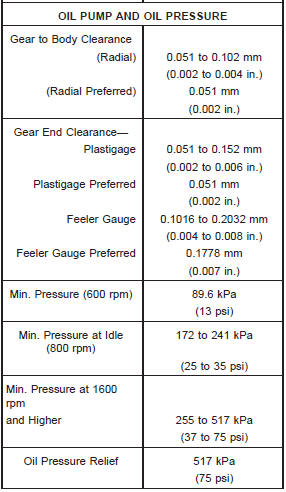

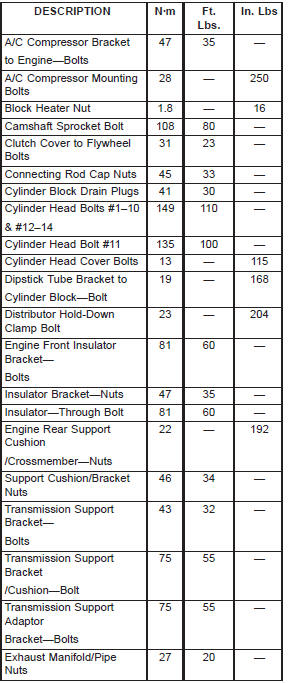

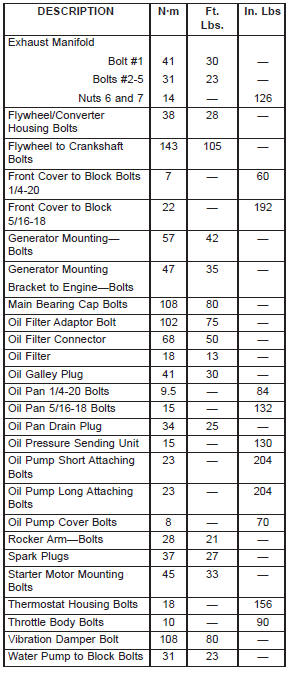

TORQUE CHART 2.5L ENGINE

Disassembly and assembly

Cleaning and inspection

Rocker arms and push rods

Engine cylinder head

Cylinder block

Fig. 89 Oil Filter Adaptor Hole

2 - OIL FILTER ADAPTOR HOLE

Fig. 90 Front Oil Galley Hole

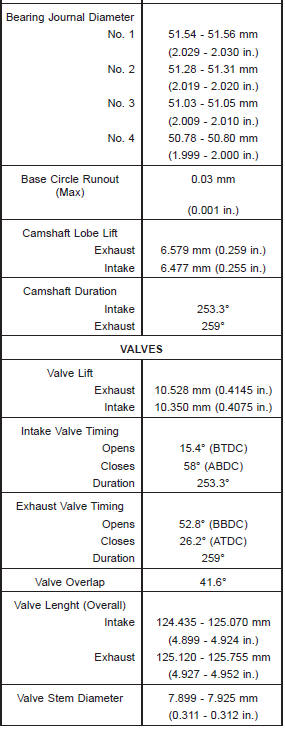

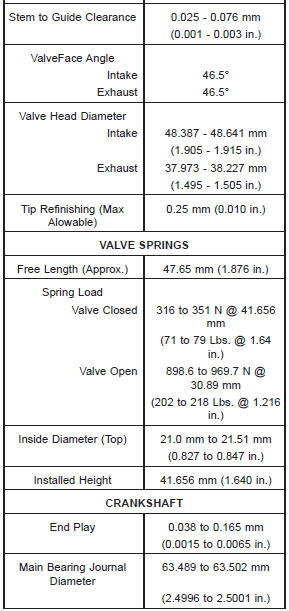

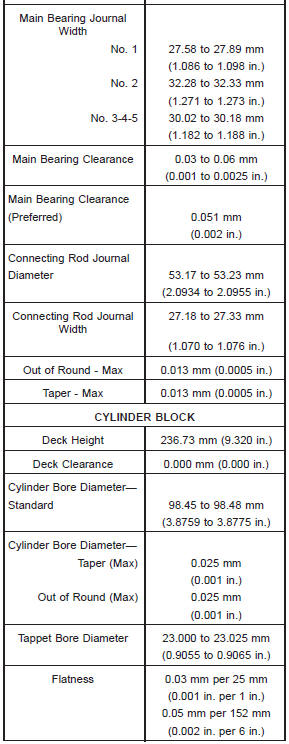

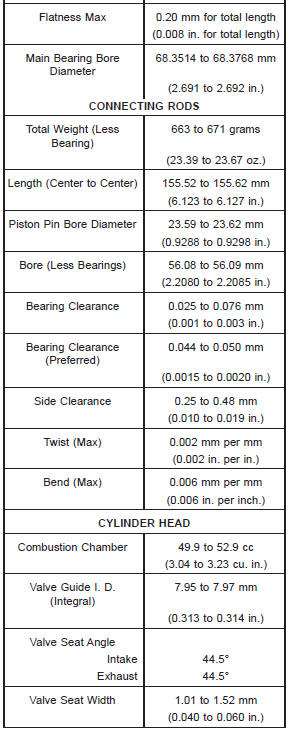

Specifications

Engine specifications

Specifications-torque

Oil pump. Piston and connecting rod. Rear main oil seal

Oil pump. Piston and connecting rod. Rear main oil seal

Other materials:

Valve timing. Valve service. Piston fitting

Valve timing

Disconnect the spark plug wires and remove the

spark plugs.

Remove the engine cylinder head cover.

Remove the capscrews, bridge and pivot assembly,

and rocker arms from above the No.1 cylinder.

Alternately loosen each capscrew, one turn at a

time, to avoid damaging the bridg ...