Jeep Cherokee (XJ): Power steering pump

DESCRIPTION Hydraulic pressure for the power steering system

is provided by a belt driven power steering pump

(Fig. 1). The pump shaft has a pressed-on high

strength plastic drive pulley that is belt driven by

the crankshaft pulley. The reservoir is attached to

the pump body with spring clips on the 4.0L engine.

A remote pump reservoir is used on the 2.5L engine

mounted to the fan shroud. The power steering pump

is connected to the steering gear by the pressure and

return hoses. OPERATION The power steering pump is a constant flow rate

and displacement, vane-type pump. The pump internal

parts operate submerged in fluid. The flow control

orifice is part of the high pressure line fitting.

The pressure relief valve inside the flow control valve

limits the pump pressure.

NOTE: Power steering pumps have different pressure

rates and are not interchangeable with other

pumps. DESCRIPTION The hose consists of two metal ends and rubber

center section that contains a tuning cable.

1 - CAP OPERATION Power steering pressure line, is used to transfer

high pressure power steering fluid, from the power

steering pump to the power steering gear. DESCRIPTION Power steering return line is a hose which is

clamped at the pump and the gear. OPERATION Power steering return line, is used to transfer low

pressure power steering fluid, from the power steering

gear to the power steering pump. The following procedure is used to test the operation

of the power steering system on the vehicle. This

test will provide the gallons per minute (GPM) or

flow rate of the power steering pump along with the

maximum relief pressure. Perform test any time a

power steering system problem is present. This test

will determine if the power steering pump or power

steering gear is not functioning properly. The following

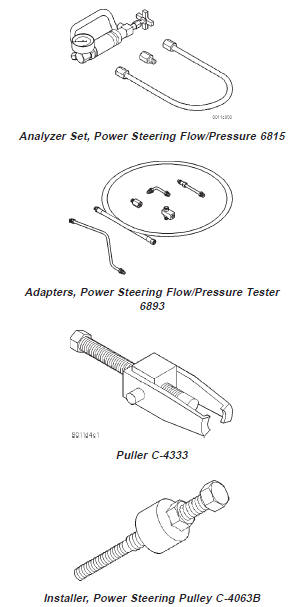

pressure and flow test is performed using Power

Steering Analyzer Tool Kit 6815 (Fig. 2) and Adapter

Kit 6893.

1 - TUBE FLOW AND PRESSURE TEST (1) Check the power steering belt to ensure it is in

good condition and adjusted properly.

(2) Connect pressure gauge hose from the Power

Steering Analyzer to Tube 6865.

(3) Connect Adapter 6826 to Power Steering Analyzer

test valve end.

(4) Disconnect high pressure hose at the pump.

Use a container for dripping fluid.

(5) Connect Tube 6865 to the pump hose fitting.

(6) Connect the power steering hose from the

steering gear to Adapter 6826.

(7) Open the test valve completely.

(8) Start engine and let idle long enough to circulate

power steering fluid through flow/pressure test

gauge and to get air out of the fluid. Then shut off

engine.

(9) Check fluid level, add fluid as necessary. Start

engine again and let idle.

(10) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure reading should be in

the range of 345-552 kPa (50-80 psi).

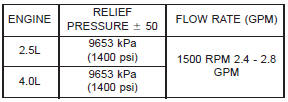

(11) Increase the engine speed to 1500 RPM and

read the flow meter. The reading should be 2.4 - 2.8

GPM, if the reading is below this specification the

pump should be replaced.

CAUTION: The next step involves testing maximum

pump pressure output and flow control valve operation.

Do not leave valve closed for more than three

seconds as the pump could be damaged.

(12) Close valve fully three times and record highest

pressure indicated each time. All three readings

must be above specifications and within

345 kPa (50 psi) of each other. (13) Open the test valve, turn steering wheel

extreme left and right positions against the stops.

Record the highest indicated pressure at each position.

Compare readings to specifications. If highest

output pressures are not the same against either

stop, the gear is leaking internally and must be

repaired.

CAUTION: Do not force the pump to operate

against the stops for more than 2 to 3 seconds at a

time because, pump damage will result. PUMP SPECIFICATIONS

POWER STEERING PUMP - INITIAL

OPERATION WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

CAUTION: Use MOPAR Power Steering Fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicate COLD when the fluid is

at normal ambient temperature.

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two minutes.

(2) Start the engine and let run for a few seconds

then turn engine off.

(3) Add fluid if necessary. Repeat the above procedure

until the fluid level remains constant after running

the engine.

(4) Raise the front wheels off the ground.

(5) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops at least 20 times.

(6) Check the fluid level add if necessary.

(7) Lower the vehicle, start the engine and turn

the steering wheel slowly from lock to lock.

(8) Stop the engine and check the fluid level and

refill as required.

(9) If the fluid is extremely foamy or milky looking,

allow the vehicle to stand a few minutes and

repeat the procedure.

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage. NOTE: The power steering pump is mounted in the

same position on LHD and RHD vehicles. On 4.0L

RHD vehicles the front bracket is different. The service

procedures are the same. REMOVAL (1) Remove serpentine drive belt, refer to Group 7

Cooling.

(2) Remove pressure and return hoses from pump,

and drain pump.

(3) Remove 3 pump mounting bolts through pulley

access holes.

(4) Loosen the 3 pump bracket bolts (Fig. 3) and

(Fig. 4).

(5) Tilt pump downward and remove from engine.

(6) Remove pulley from pump. INSTALLATION (1) Install pulley on pump.

(2) Install pump on engine.

(3) Tighten pump bracket bolts to 47 N·m (35 ft.

lbs.).

(4) Install 3 pump mounting bolts and tighten to

27 N·m (20 ft. lbs.).

(5) Install the pressure and return hoses to pump.

(6) Install drive belt, refer to Group 7 Cooling.

(7) Add power steering fluid and perform Power

Steering Pump Initial Operation. REMOVAL (1) Remove the hoses from the bottom of the reservoir

and drain the reservoir.

(2) Remove the push-in fastener from the top of

the fan shroud.

(3) Slide reservoir up off the fan shroud. INSTALLATION (1) Slide reservoir down onto fan shroud.

(2) Install the push-in fastener in the top of fan

shroud.

1 - PUMP BRACKET (3) Install the pump hoses.

(4) Fill reservoir to proper level. Refer to Power

Steering Pump Initial Operation. DISASSEMBLY (1) Remove pump assembly.

(2) Remove pulley from pump with Puller C-4333

or equivalent puller (Fig. 5). ASSEMBLY NOTE: The pulley is marked front for installation.

(1) Replace pulley if bent, cracked, or loose.

(2) Install pulley on pump with Installer C-4063-B

or equivalent installer (Fig. 6). The pulley must be

flush with the end of the shaft. Ensure the tool and

pulley are aligned with the pump shaft.

(3) Install pump assembly.

(4) With Serpentine Belt, run engine until warm (5

min.) and note any belt chirp. If chirp exists, move

pulley outward approximately 0.5 mm (0.020 in.). If

noise increases, press on 1.0 mm (0.040 in.). Be

careful that pulley does not contact mounting

bolts. DISASSEMBLY (1) Remove power steering pump.

(2) Clean exterior of pump.

(3) Clamp the pump body in a soft jaw vice.

(4) Pry up tab and slide the retaining clips off (Fig.

7).

NOTE: Use new retaining clips for installation.

(5) Remove fluid reservoir from pump body.

Remove and discard O-ring seal. ASSEMBLY (1) Lubricate new O-ring Seal with Mopar Power

Steering Fluid or equivalent.

1 - BRACKET

1 - POWER STEERING PUMP DRIVE PULLEY (2) Install O-ring seal in housing.

(3) Install reservoir onto housing.

(4) Slide and tap in new reservoir retainer clips

until tab locks to housing.

1 - POWER STEERING PUMP DRIVE PULLEY (5) Install power steering pump.

(6) Add power steering fluid, refer to Pump Initial

Operation.

1 - RESERVOIR TORQUE CHART DESCRIPTION TORQUE Power Steering Pump Bracket to Pump . . . . . . . . . . 28 N·m (21 ft. lbs.) POWER STEERING PUMP

Description and operation

Power steering pump

Power steering pressure line

Fig. 1 Pump With Integral Reservoir

2 - FLUID RESERVOIR (TYPICAL)

3 - HIGH-PRESSURE FITTING

4 - DRIVE PULLEY

5 - PUMP BODY

6 - RESERVOIR CLIPPower steering return line

Diagnosis and testing

Power flow and pressure

Fig. 2 Power Steering Analyzer

2 - ADAPTER FITTINGS

3 - ANALYZER

4 - GAUGE HOSE

Pump leakage diagnosis

Service procedures

Removal and installation

Power steering pump

Pump reservoir-2.5L

Fig. 3 Pump Mounting LHD

2 - PUMP ASSEMBLY 2.5L

3 - PUMP ASSEMBLY 4.0LDisassembly and assembly

Pump pulley

Pump reservoir

Fig. 4 Pump Mounting 4.0L RHD

2 - PUMP ASSEMBLY

Fig. 5 Pulley Removal

2 - SPECIAL TOOL C-4333

Fig. 6 Pulley Installation

2 - SPECIAL TOOL C-4063-B

Fig. 7 Pump Reservoir Clips

2 - RETAINING CLIPSSpecifications

Bracket to Engine . . . . . . . . . 47 N·m (35 ft. lbs.)

Flow Control Valve . . . . . . . . 75 N·m (55 ft. lbs.)

Pressure Line . . . . . . . . . . . . . 28 N·m (21 ft. lbs.)Special tools

Other materials:

Disassembly and assembly

Master cylinder reservoir

REMOVAL

(1) Remove reservoir cap and empty fluid into

drain container.

(2) Remove pins that retain reservoir to master

cylinder. Use hammer and pin punch to remove pins

(Fig. 40).

Fig. 40 Reservoir Retaining Pins

1 - PIN PUNCH

2 - RESERVOIR

3 - BODY

4 - ROLL ...