Jeep Cherokee (XJ): Diagnosis and testing

When diagnosing the turn signal or hazard warning

circuits, remember that high generator output

can burn out bulbs rapidly and repeatedly. If this is a

problem on the vehicle being diagnosed, refer to

Charging System in the Diagnosis and Testing section

of Group 8C - Charging System for further diagnosis

of a possible generator overcharging condition.

If the problem being diagnosed is related to a failure

of the turn signals to automatically cancel following

completion of a turn, inspect the multi-function

switch for a faulty or damaged cancel actuator and

inspect the turn signal cancelling cam lobes on the

clockspring mechanism for damage or improper

installation. For complete circuit diagrams, refer to

Turn Signals in the Contents of Group 8W - Wiring

Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG

DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Turn the ignition switch to the On position.

Actuate the turn signal switch or the hazard warning

switch. Observe the turn signal indicator lamp(s) in

the instrument cluster. If the flash rate is very high,

check for a turn signal bulb that is not lit or is very

dimly lit. Repair the circuits to that lamp or replace

the faulty bulb, as required. If the turn signal indicator(

s) fail to light, go to Step 2.

(2) Turn the ignition switch to the Off position.

Check the turn signal fuse in the junction block

and/or the hazard warning fuse in the Power Distribution

Center (PDC). If OK, go to Step 3. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse(s).

(3) Check for battery voltage at the hazard warning

fuse in the PDC. If OK, go to Step 4. If not OK,

repair the open fused B(+) circuit to the battery as

required.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the turn signal fuse in

the fuseblock module. If OK, go to Step 5. If not OK,

repair the open fused ignition switch output (accessory/

run) circuit to the ignition switch as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the combination flasher from its wire harness

connector and replace it with a known good

unit. Connect the battery negative cable. Test the

operation of the turn signal and hazard warning systems.

If OK, discard the faulty combination flasher.

If not OK, remove the test flasher and go to Step 6.

(6) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (accessory/run) circuit cavity in the combination

flasher wire harness connector. If OK, go to Step

7. If not OK, go to Step 9. (7) Turn the ignition switch to the Off position.

Place the hazard warning switch in the On position.

Check for battery voltage again at the fused B+ circuit

cavity in the combination flasher wire harness

connector. If OK, go to Step 8. If not OK, go to Step 9.

(8) Disconnect and isolate the battery negative

cable. Check for continuity between the ground circuit

cavity of the combination flasher wire harness

connector and a good ground. There should be continuity.

If OK, go to Step 9. If not OK, repair the open

ground circuit to ground as required.

(9) Disconnect the instrument panel wire harness

connector from the multi-function switch connector

receptacle. Check for continuity between the turn signal

output circuit cavities in the combination flasher

wire harness connector and in the instrument panel

wire harness connector for the multi-function switch.

There should be continuity. If OK, go to Step 10. If

not OK, repair the open turn signal output circuit as

required.

(10) Check for continuity between the hazard

warning output circuit cavities in the combination

flasher wire harness connector and in the instrument

panel wire harness connector for the multi-function

switch. There should be continuity. If OK, refer to

Turn Signal Switch and Hazard Warning Switch

in the Diagnosis and Testing section of this group. If

not OK, repair the open hazard warning output circuit

as required. The turn signal switch and the hazard warning

switch are integral to the multi-function switch.

Refer to Turn Signal and Hazard Warning Systems

in the Diagnosis and Testing section of this

group before testing the multi-function switch. For

complete circuit diagrams, refer to Turn Signals in

the Contents of Group 8W - Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

REFER TO GROUP 8M - PASSIVE RESTRAINT

SYSTEMS BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector from the multi-function switch connector

receptacle.

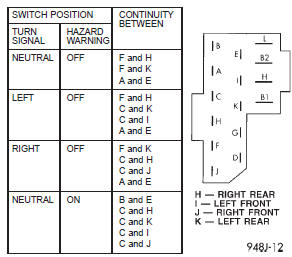

(2) Using an ohmmeter, perform the switch continuity

checks at the connector receptacle terminals as

shown in the Multi-Function Switch Continuity chart

(Fig. 3).

(3) If the turn signal switch or hazard warning

switch fails any of the continuity checks, replace the

faulty multi-function switch assembly as required. If

the switch circuits are OK, repair the lighting circuits

as required.Turn signal and hazard warning

systems

Turn signal switch and hazard

warning switch

Fig. 3 Multi-Function Switch Continuity

Other materials:

Introducing Uconnect. Get Started. Basic Voice Commands

Introducing Uconnect

Start using Uconnect Voice Recognition with these helpful

quick tips. It provides the key Voice Commands and

tips you need to know to control your Uconnect 5.0 or

8.4A/8.4AN system.

Uconnect 5.0

Key Features:

5" touchscreen

Three buttons on either side of the disp ...