Jeep Cherokee (XJ): Starter motor noise - 2.5L engine. Starter motor. Starter relay

See the Starter Motor Noise Diagnosis chart (Fig.

9). If the complaint is similar to Conditions 1 and 2

in the chart, correction can be made by placing shims

between the starter motor and the engine block using

the following procedures: CONDITION POSSIBLE CAUS CORRECTION NOTE: A high frequency whine during cranking is normal for this

starter motor. FIG. 9 STARTER MOTOR NOISE DIAGNOSIS (1) If the complaint is similar to Condition 1, the

starter motor must be moved toward the starter ring

gear by removing shims from both starter mounting

pads on the engine block (Fig. 10). Refer to Starter

Motor in the index of this service manual for the

location of the proper starter motor removal and

installation procedures.

NOTE: The shim thickness is 0.381 mm (0.015 in.).

These shims may be stacked if additional thickness

is required.

1 - STARTER MOTOR SHIM (2) If the complaint is similar to Condition 2, the

starter motor must be moved away from the starter

ring gear. This is done by installing shim(s) across

both starter mounting pads on the engine block.

More than one shim may be required. Refer to

Starter Motor in the index of this service manual

for the location of the proper removal and installation

procedures.

NOTE: This is a condition that will generally cause

broken starter (flywheel/torque converter drive

plate) ring gear teeth or broken starter motor housings. Correct starter motor operation can be confirmed

by performing the following free running bench test.

This test can only be performed with the starter

motor removed from the vehicle. Refer to Starting

System in the index of this service manual for the

location of the proper starter motor specifications.

CAUTION: The 2.5L engine uses a permanent magnet

starter. Permanent magnet starters are highly

sensitive to hammering, shocks, external pressure

and reverse polarity. This starter motor must never

be clamped in a vise by the starter field frame. The

starter should only be clamped by the mounting

flange. Do not reverse the battery cable connections

to this starter motor when testing. The permanent

magnets may be damaged and the starter

rendered unserviceable if it is subjected to any of

these conditions. STARTER MOTOR (1) Remove the starter motor from the vehicle.

Refer to Starter Motor in the index of this service

manual for the location of the proper starter motor

removal and installation procedures.

(2) Mount the starter motor securely in a softjawed

bench vise. The vise jaws should be clamped

on the mounting flange of the starter motor. Never

clamp on the starter motor by the field frame.

(3) Connect a suitable volt-ampere tester and a

12-volt battery to the starter motor in series, and set

the ammeter to the 100 ampere scale. See the

instructions provided by the manufacturer of the

volt-ampere tester being used.

(4) Install a jumper wire from the solenoid terminal

to the solenoid B(+) terminal stud. The starter

motor should operate. If the starter motor fails to

operate, replace the faulty starter motor.

(5) Adjust the carbon pile load of the tester to

obtain the free running test voltage. Refer to Starting

System in the index of this service manual for

the location of the proper starter motor free running

test voltage specifications.

(6) Note the reading on the ammeter and compare

this reading to the free running test maximum

amperage draw. Refer to Starting System in the

index of this service manual for the location of the

proper starter motor free running test maximum

amperage draw specifications.

(7) If the ammeter reading exceeds the maximum

amperage draw specification, replace the faulty

starter motor. STARTER SOLENOID This test can only be performed with the starter

motor removed from the vehicle.

(1) Remove the starter motor from the vehicle.

Refer to Starter Motor in the index of this service

manual for the location of the proper starter motor

removal and installation procedures.

(2) Disconnect the wire from the solenoid field coil

terminal.

(3) Check for continuity between the solenoid terminal

and the solenoid field coil terminal with a continuity

tester (Fig. 11). There should be continuity. If

OK, go to Step 4. If not OK, replace the faulty starter

motor.

(4) Check for continuity between the solenoid terminal

and the solenoid case (Fig. 12). There should

be continuity. If not OK, replace the faulty starter

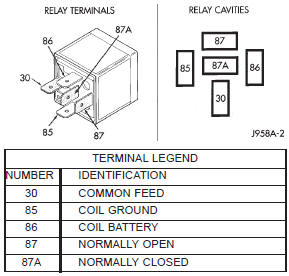

motor. The starter relay (Fig. 13) is located in the Power

Distribution Center (PDC), in the engine compartment.

Refer to the fuse and relay layout label affixed to the underside of the PDC

cover for starter relay

identification and location. Refer to Starting System

in the index of this service manual for the location

of complete starting system wiring diagrams.

1 - SOLENOID

2 - SOLENOID TERMINAL

3 - OHMMETER

4 - FIELD COIL TERMINAL

1 - SOLENOID

2 - SOLENOID TERMINAL

3 - OHMMETER RELAY TEST (1) Remove the starter relay from the PDC. Refer

to Starter Relay in the index of this service manual

for the location of the proper starter relay removal

and installation procedures.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (electromagnet)

should be 75 6 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay

RELAY CIRCUIT TEST (1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fused B(+) fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is connected

to the common feed terminal (30) in the energized

position. This terminal supplies battery voltage

to the starter solenoid field coil. There should be continuity

between the cavity for relay terminal 87 and

the starter solenoid terminal at all times. If OK, go

to Step 4. If not OK, repair the open engine starter

motor relay output circuit to the starter solenoid as

required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the Start position. On

vehicles with a manual transmission, the clutch

pedal must be blocked in the fully depressed position

for this test. Check for battery voltage at the cavity

for relay terminal 86 with the ignition switch in the

Start position, and no voltage when the ignition

switch is released to the On position. If OK, go to

Step 5. If not OK with a manual transmission, disconnect

the clutch pedal position switch wire harness

connector and install a jumper wire between the two

cavities in the body half of the connector and check

for battery voltage again at the cavity for relay terminal

86. If now OK, replace the faulty clutch pedal

position switch. If still not OK with a manual transmission

or if not OK with an automatic transmission,

check for an open or shorted fused ignition switch

output (start) circuit to the ignition switch and

repair, as required. If the fused ignition switch output

(start) circuit is OK, refer to Ignition Switch

and Key Lock Cylinder in the index of this service

manual for the location of the proper ignition switch

diagnosis and testing procedures.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. On vehicles with a

manual transmission, it is grounded at all times. On

vehicles with an automatic transmission, it is

grounded through the park/neutral position switch

only when the gearshift selector lever is in the Park

or Neutral positions. Check for continuity to ground

at the cavity for relay terminal 85. If not OK with a

manual transmission, repair the open park/neutral

position switch sense circuit to ground as required. If

not OK with an automatic transmission, check for an

open or shorted park/neutral position switch sense

circuit to the park/neutral position switch and repair,

as required. If the park/neutral position switch sense

circuit checks OK, refer to Park/Neutral Position

Switch in the index of this service manual for the

location of the proper park/neutrStarter motor noise - 2.5L engine

1. VERY HIGH FREQUENCY

WHINE BEFORE ENGINE

STARTS; ENGINE STARTS OK.

1. Excessive distance between pinion

gear and flywheel/drive plate gear.

1. Move starter motor toward

flywheel/drive plate by removing

shim(s), if possible.

2. VERY HIGH FREQUENCY

WHINE AFTER ENGINE STARTS

WITH IGNITION KEY RELEASED.

ENGINE STARTS OK.

2. Insufficient distance between

starter motor pinion gear and

flywheel/drive plate runout can cause

noise to be intermittent.

2. Shim starter motor away from

flywheel/drive plate. Inspect

flywheel/drive plate for damage;

bent, unusual wear, and excessive

runout. Replace flywheel/drive

plate as necessary.

3. A LOUD "WHOOP" AFTER

ENGINE STARTS WHILE

STARTER MOTOR IS ENGAGED.

3. Most probably cause is defective

overrunning clutch.

3. Replace starter motor.

4. A "RUMBLE," "GROWL," OR

"KNOCK" AS STARTER MOTOR

COASTS TO STOP AFTER

ENGINE STARTS.

4. Most probable cause is bent or

unbalanced starter motor armature.

4. Replace starter motor.

Fig. 10 Starter Motor ShimStarter motor

Starter relay

Fig. 11 Continuity Test Between Solenoid Terminal and Field Coil Terminal

- Typical

Fig. 12 Continuity Test Between Solenoid Terminal and Solenoid Case -

Typical

Fig. 13 Starter Relay

Other materials:

Important Safety Precautions. Seat Belt Systems

Important Safety Precautions

Please pay close attention to the information in this

section. It tells you how to use your restraint system

properly, to keep you and your passengers as safe as

possible.

Here are some simple steps you can take to minimize the

risk of harm from a deploying air ba ...