Jeep Cherokee (XJ): Valve timing. Valve, guide and seal. Piston-fitting

Clean all carbon deposits from the combustion

chambers, valve ports, valve stems, valve stem

guides and head.

Clean all grime and gasket material from the

engine cylinder head machined gasket surface.

Inspect for cracks in the combustion chambers and

valve ports.

Inspect for cracks on the exhaust seat.

Inspect for cracks in the gasket surface at each

coolant passage.

Inspect valves for burned, cracked or warped

heads.

Inspect for scuffed or bent valve stems.

Replace valves displaying any damage. VALVE REFACING (1) Use a valve refacing machine to reface the

intake and exhaust valves to the specified angle.

(2) After refacing, a margin of at least 0.787 mm

(0.031 inch) must remain (Fig. 13). If the margin is

less than 0.787 mm (0.031 inch), the valve must be

replaced. VALVE SEAT REFACING (1) Install a pilot of the correct size in the valve

guide bore. Reface the valve seat to the specified

angle with a good dressing stone. Remove only

enough metal to provide a smooth finish.

(2) Use tapered stones to obtain the specified seat

width when required.

(3) Control valve seat runout to a maximum of

0.0635 mm (0.0025 in.)- (Fig. 14). VALVE STEM OIL SEAL REPLACEMENT Valve stem oil seals are installed on each valve

stem to prevent rocker arm lubricating oil from

entering the combustion chamber through the valve

guide bores. One seal is marked INT (intake valve)

and the other is marked EXH (exhaust valve).

Replace the oil seals whenever valve service is performed

or if the seals have deteriorated.

1 - 0.787 MM (1/32 INCH) VALVE MARGIN

1 - DIAL INDICATOR VALVE GUIDES The valve guides are an integral part of the engine

cylinder head and are not replaceable.

When the valve stem guide clearance is excessive,

the valve guide bores must be reamed oversize. Service

valves with oversize stems are available in 0.076

mm (0.003 inch) and 0.381 mm (0.015 inch) increments.

Corresponding oversize valve stem seals are also

available and must be used with valves having 0.381

mm (0.015 inch) oversize stems, 0.076mm (.003in.)

oversize stems do not require oversize seals.

NOTE: If the valve guides are reamed oversize, the

valve seats must be ground to ensure that the valve

seat is concentric to the valve guide. VALVE STEM-TO-GUIDE CLEARANCE

MEASUREMENT Valve stem-to-guide clearance may be measured by

either of the following two methods. PREFERRED METHOD: (1) Remove the valve from the head.

(2) Clean the valve stem guide bore with solvent

and a bristle brush.

(3) Insert a telescoping gauge into the valve stem

guide bore approximately 9.525 mm (.375 inch) from

the valve spring side of the head (Fig. 15).

1 - GAUGE (4) Remove and measure telescoping gauge with a

micrometer.

(5) Repeat the measurement with contacts lengthwise

to engine cylinder head.

(6) Compare the crosswise to lengthwise measurements

to determine out-of-roundness. If the measurements

differ by more than 0.0635 mm (0.0025 in.),

ream the guide bore to accommodate an oversize

valve stem.

(7) Compare the measured valve guide bore diameter

with specifications (7.95-7.97 mm or 0.313-0.314 inch). If the measurement

differs from specification

by more than 0.076 mm (0.003 inch), ream the guide

bore to accommodate an oversize valve stem. ALTERNATIVE METHOD: (1) Use a dial indicator to measure the lateral

movement of the valve stem (stem-to-guide clearance).

This must be done with the valve installed in

its guide and just off the valve seat (Fig. 16).

(2) Correct clearance is 0.025-0.0762 mm

(0.001-0.003 inch). If indicated movement exceeds the

specification ream the valve guide to accommodate

an oversize valve stem.

NOTE: Valve seats must be ground after reaming

the valve guides to ensure that the valve seat is

concentric to the valve guide.

1 - DIAL INDICATOR VALVE SPRING TENSION TEST Use a Universal Valve Spring Tester and a torque

wrench to test each valve spring for the specified tension

value (Fig. 17).

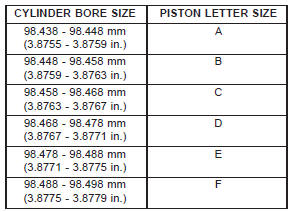

Replace valve springs that are not within specifications. BORE GAUGE METHOD (1) To correctly select the proper size piston, a cylinder

bore gauge, capable of reading in 0.003 mm

(.0001 in.) INCREMENTS is required. If a bore

gauge is not available, do not use an inside micrometer.

1 - TORQUE WRENCH (2) Measure the inside diameter of the cylinder

bore at a point 49.5 mm (1-15/16 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 19).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled. The

coated piston connecting rod assembly can be

used to service previous built engines and

MUST be replaced as complete sets. Tin coated

pistons should not be used as replacements for coated

pistons.

(4) The coating material is applied to the piston

after the final piston machining process. Measuring

the outside diameter of a coated piston will not provide

accurate results (Fig. 18). Therefore measuring

the inside diameter of the cylinder bore with a dial

Bore Gauge is MANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable of

reading in 0.003 mm (.0001 in.) increments is

required.

(5) Piston installation into the cylinder bore

requires slightly more pressure than that required

for non-coated pistons. The bonded coating on the

piston will give the appearance of a line-to-line fit

with the cylinder bore.

1 - MOLY COATED

1 - FRONT PISTON SIZE CHART

Valve timing

Valve, guide and seal

Fig. 13 Valve Facing Margin

2 - NO MARGIN

Fig. 14 Measurement of Valve Seat Runout

Fig. 15 Measurement of Valve Guide Bore Diameter

2 - 9.525 MM (3/8 INCH)

3 - VALVE STEM GUIDE

4 - CYLINDER HEAD

Fig. 16 Measurement of Lateral Movement Of Valve StemPiston-fitting

Fig. 17 Valve Spring Tester

2 - VALVE SPRING TESTER

Fig. 18 Moly Coated Piston

2 - MOLY COATED

Fig. 19 Bore Gauge

2 - BORE GAUGE

3 - CYLINDER BORE

4 - 49.5 MM

(1-15/16 in)

Other materials:

Removal and installation

SENTRY KEY IMMOBILIZER MODULE

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

REFER TO GROUP 8M - PASSIVE RESTRAINT SYSTEMS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL ...